MCQ Subjects

Choose from a wide range of subjects to practice multiple-choice questions and test your knowledge effectively.

Exams

Prepare for your next test with our collection of exam-based practice sets and question banks designed for effective assessment and revision.

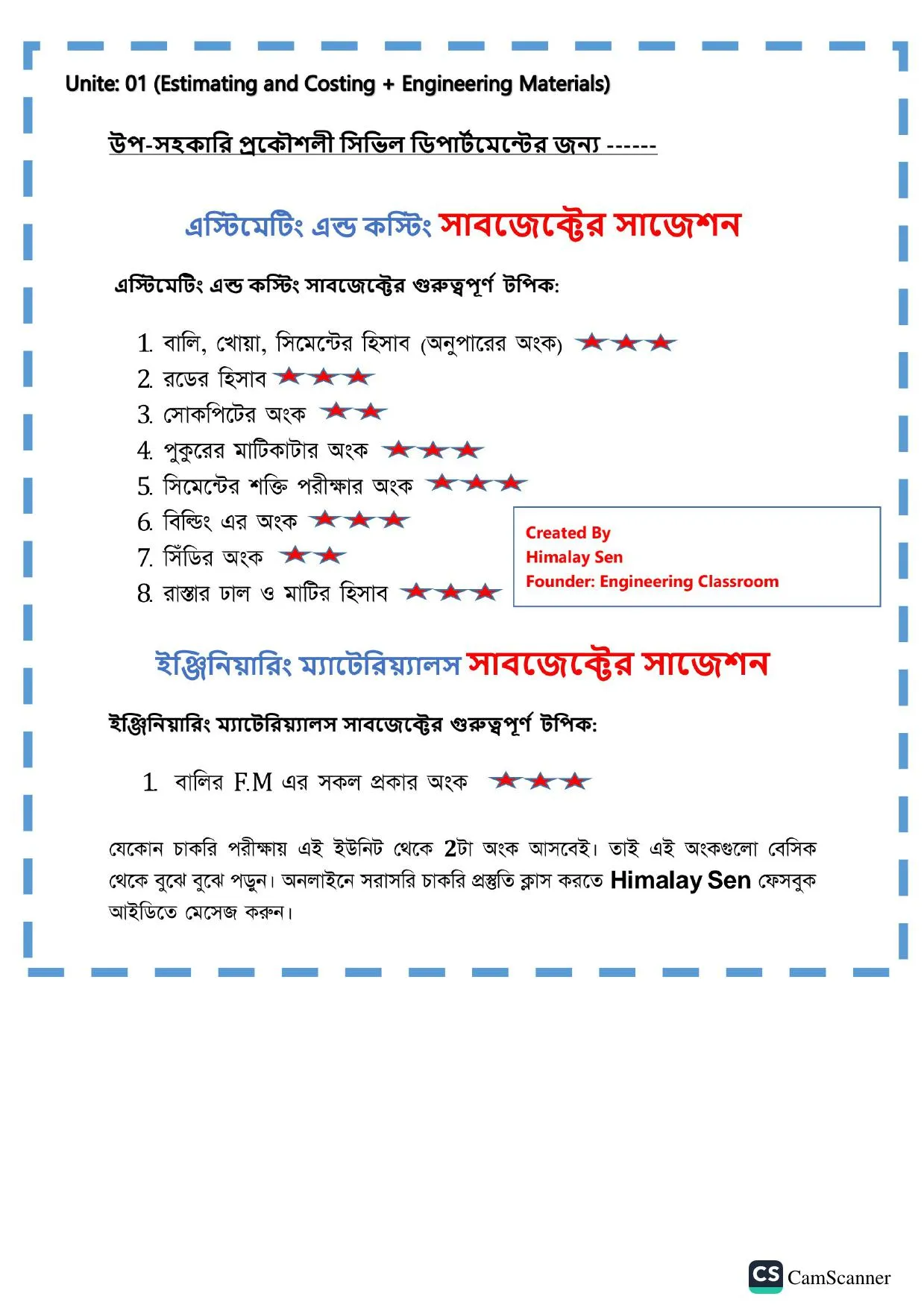

Courses

Discover our wide range of online courses designed to help you learn new skills, master complex topics, and achieve your academic or career goals.

Popular Courses

Categories

Start Learning Today

Join over 19,373 students and advance your career with expert-led courses

Get StartedBoard Questions

Access past board exam questions organized by year and subject to help you understand patterns, improve preparation, and boost your exam performance.

More

Explore additional sections of our platform, including About, Jobs, Posts, Notices and other useful resources to stay informed and connected.